MCAI Market Vision: The Future of AI Data Center Reliability, Predictive Foresight for AI Infrastructure

Digital Twins, Non-Destructive Evaluation and Cognitive Digital Twins for Data Center Ecosystems

See also MCAI Market Vision: The Bottleneck Hierarchy in U.S. AI Data Centers (Aug 2025), Predictive Cognitive AI and the AI Infrastructure Ecosystem (Oct 2025).

Executive Summary

In 2026–2027, multibillion-dollar data centers will experience cascading cooling failures. The digital twins will flag the issue six hours before shutdown. Yet the damage began 18 months earlier, in a material defect no one inspected. The purpose of this vision statement is to close that gap—to build foresight systems that can see not only when something will fail, but why, and how to prevent it.

The global AI infrastructure race accelerates toward a frontier few acknowledge: the physical integrity of the data center itself. As energy density, water use, and capital intensity reach record levels, reliability shifts from algorithmic performance to material endurance.

AI data centers now operate as thermodynamic organisms, balancing electrical, mechanical, and cognitive stress in real time. The decade ahead will favor those who sustain their infrastructure—not just those who scale it.

To achieve that, the industry must draw from a discipline born in large-scale engineering systems: Non-Destructive Evaluation (NDE)—the science of seeing inside matter without breaking it. MindCast AI integrates these reliability sciences into a Cognitive Digital Twin (CDT) that extends inspection and monitoring into foresight, helping institutions predict where anomalies will emerge, how they propagate, and what actions will sustain trust over time.

Contact mcai@mindcast-ai.com to partner with us on predictive cognitive AI for AI infrastructure.

I. The Hidden Frontier of AI Infrastructure

Complacency—not ignorance—is the true threat. Across the data center landscape, reliability management has devolved into reactive maintenance cultures, siloed monitoring tools, and reliability theater—busy dashboards that simulate control without foresight. These approaches reward short-term uptime at the expense of long-term understanding.

Every modern data center concentrates megawatts of power and billions in capital into a single location. Performance depends on structural, thermal, and electrical integrity across thousands of components. Yet reliability often remains an afterthought. Cooling, vibration, and corrosion are monitored but rarely modeled with precision. Inspection cycles trail behind expansion schedules. Failures are discovered only after downtime.

At scale, that gap will widen. The physical substrate of AI—racks, conduits, manifolds, and composite housings—demands predictive rigor once reserved for aerospace and nuclear engineering.

II. Lessons from Integrity Sciences

Industries that manage extreme conditions—aviation, energy, heavy manufacturing—learned decades ago to detect invisible flaws before failure. They pioneered Non-Destructive Evaluation (NDE): ultrasonic, radiographic, and electromagnetic techniques for mapping internal structures without harm.

NDE merged trust with transparency in systems too complex to disassemble. Engineers learned to reason from internal signals rather than surface appearances. That same mindset—seeing without breaking—now defines the future of AI infrastructure.

The future of reliability belongs to industries that learned to see inside complexity before computation scaled.

III. From Design to Perception: The Digital-Twin Continuum

Data centers already rely on digital twins to simulate thermal and electrical behavior in real time. Sensors feed temperature, vibration, and power data into models that flag anomalies before catastrophic failure. These systems serve as the nervous system of compute infrastructure.

Yet digital twins stop at detection. They identify what is happening but not why or how it will evolve. A temperature spike might signal material fatigue or environmental stress, but current systems can’t trace its cause or consequence.

When digital twins flag an anomaly, NDE techniques validate it—ultrasonic or acoustic imaging locates microfractures, voids, or corrosion. That verified insight becomes the ground truth feeding the simulation. MindCast AI extends this continuum by adding a cognitive foresight layer that integrates both data streams to model the future probability of anomalies before they appear.

IV. The Cognitive Digital Twin for Living Infrastructure

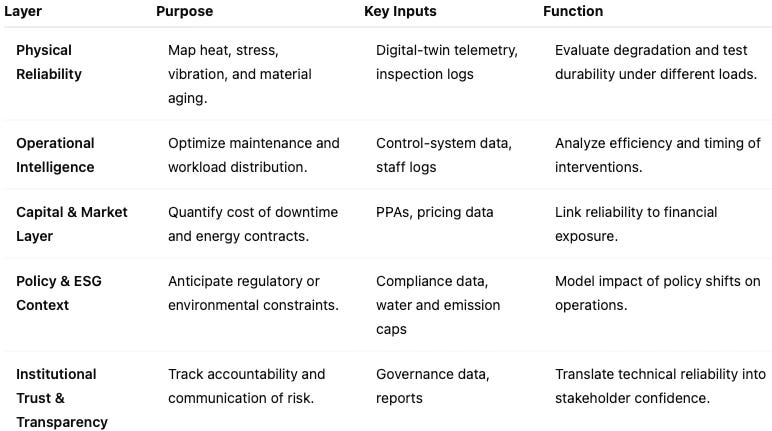

A Cognitive Digital Twin unifies technical, operational, financial, policy, and trust data into one living model. This integration creates synergy beyond what isolated tools can deliver. While separate systems optimize for their own silos—engineering for performance, finance for efficiency, compliance for safety—the CDT links them so each decision strengthens the rest.

By converging these perspectives, the CDT uncovers risks invisible to any single dataset. A small thermal anomaly, when combined with regulatory water-use limits and an expiring power contract, may signal a reliability cliff months before it happens. Unified foresight turns fragmented monitoring into coordinated intelligence, giving decision-makers an early, quantified view of how physical, financial, and policy pressures converge.

Functional Layers

These five layers let the CDT test not one future but thousands—each combining physical, operational, market, policy, and trust data to reveal converging risk. For example, thermal readings may look stable, yet when combined with regulatory and market data, the CDT may forecast an 18% overheating risk and $40 million in downtime losses next quarter if a regional power contract lapses.

V. Spatial–Temporal Reliability Intelligence

Modern visualization tools now merge AR/VR interfaces, digital twins, and laser-linked inspection. Engineers can point a laser at a component and instantly see its digital-twin data—stress maps, defect history, predicted fatigue curves—overlaid in augmented reality. Human and machine share the same object in both physical and data space.

Temporal foresight completes the picture. MindCast AI’s CDT projects how anomalies migrate and compound over time, revealing whether a current stress point will trigger cascading failures or self-stabilize under new conditions.

Spatial and temporal foresight close the loop between where, what, and when—the coordinates of modern reliability.

VI. Predicting Future Anomalies

Anomalies signal opportunity, not failure. Each event becomes a learning input that sharpens predictive accuracy.

MindCast AI’s foresight layer ingests three categories of data:

Continuous digital-twin telemetry (thermal, electrical, acoustic)

Periodic NDE inspections (validated defect data)

Environmental and operational context (load, humidity, supply stress)

The CDT identifies which variables consistently precede degradation and evolves a predictive map of emerging risk. When cooling-loop alloys show similar microfractures across sites, the model raises an alert months before recurrence. When vibration harmonics align with power fluctuations, the system simulates how rebalancing workloads can prevent resonance failures.

Transparent scoring verifies each causal link, converting detection into foresight—turning data into preemptive action.

VII. Advanced Material Intelligence

As data centers approach physical limits, materials innovation becomes central. Composites, dielectrics, and phase-change alloys each behave differently under constant load. Techniques once used to validate aircraft structures can now safeguard immersion-cooling tanks and support panels. Micro-anomaly detection from turbine inspection can expose voids in manifolds before leaks form.

Adopting a materials-aware reliability culture transforms maintenance into continuous learning. Data and matter evolve together, producing infrastructure that anticipates its own decay.

The integrity lessons of large-scale infrastructure now anchor the reliability vocabulary of large-scale computation.

VIII. From Monitoring to Meaning

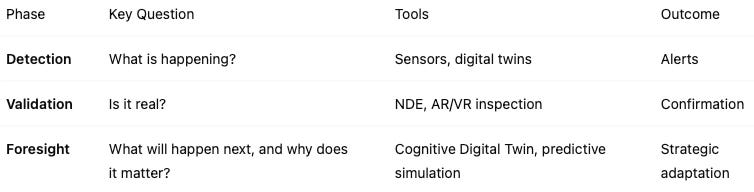

Digital twins monitor. NDE validates. Cognitive foresight interprets.

Current analytics remain descriptive—heat maps and uptime dashboards that lack context. As complexity increases, noise overwhelms insight. MindCast AI compresses years of operational evolution into actionable foresight, translating telemetry into guidance that executives can act on.

The loop—Detect → Confirm → Foresee—defines the new benchmark for operational confidence.

IX. Predictive Infrastructure as a Learning System

Integrated layers turn the data center into a learning organism. Each inspection, maintenance action, or stress event refines the CDT, sharpening accuracy and foresight. Repair data immediately updates the model’s understanding of material behavior and risk thresholds.

For example, a cooling pump failure in one region triggers maintenance. The CDT records pre-failure vibration and thermal data. When similar patterns surface elsewhere, it predicts likely failures weeks in advance. Each cycle of detection and correction strengthens the model’s global foresight.

Feedback transforms maintenance from cost to intelligence. The data center calibrates itself continuously—predictions grow sharper with every correction, foresight deeper with each lesson.

Reliability evolves into trust infrastructure—a measurable integrity standard verifiable by regulators, investors, and communities.

Predictive infrastructure is the moral architecture of computation: it keeps intelligence honest by keeping matter understood.

X. The Foresight Layer

MindCast AI operates as a cloud-native foresight platform that ingests digital-twin streams and NDE reports, running continuous Monte Carlo simulations across physical, financial, and policy scenarios. The system identifies emerging vulnerabilities, quantifies downstream impacts, and prioritizes interventions long before problems reach a crisis point.

Operational Role

The platform functions as middleware between existing monitoring stacks and business intelligence tools. It pulls live sensor data from operational systems, merges it with inspection and regulatory datasets, and surfaces predictive alerts directly into executive dashboards. Decision-makers gain a unified picture of how engineering risks translate into financial and policy outcomes.

Integration Advantage

MindCast AI integrates seamlessly within the existing ecosystem—no rip-and-replace required. It builds on the data enterprises already generate and enhances its value by converting raw telemetry into actionable foresight. Real-time forecasts allow organizations to act on trend signals weeks or months before failure.

What It Replaces

The foresight layer eliminates reactive war rooms and post-mortem culture, replacing endless incident reviews with forward planning. Teams move from firefighting to foresight, allocating resources before anomalies escalate. The result is a proactive reliability culture that anticipates failure, prevents loss, and strengthens institutional confidence.

The foresight layer transforms the way data centers make decisions—shifting reliability management from reaction to prediction.

XI. Why Now. Why Now

By 2030, more than $500 billion in AI infrastructure will face integrity crises that current monitoring systems cannot predict. Each new megawatt adds not just energy demand but risk. As sites expand into geologically and climatically diverse regions, the cost of misunderstanding material behavior multiplies.

The industry has mastered digital scale; its next challenge is physical cognition. Integrating NDE expertise, immersive visualization, and cognitive foresight will make AI infrastructure more powerful and more sustainable—an ecosystem that learns without breaking.

XII. Conclusion: Seeing Before Breaking

Civilization’s intelligence is measured not by what it builds, but by how well it perceives what it has built. Non-Destructive Evaluation gave humanity the power to look inward—into structures, engines, and systems—without destruction. Cognitive foresight extends that power forward—into the future behavior of the infrastructure sustaining our digital world.

MindCast AI aims to make foresight the foundation of reliability, ensuring that as computation accelerates, the physical systems supporting it remain coherent, predictable, and trustworthy.

The future belongs to those who can see inside matter and ahead in time—without breaking either.